1. Introduction

2. Application

Lubricant

Zinc Sulfide has good lubricating property as a solid lubricating additive. LS-G25 can be used as lubricant to avoid the elastomer plastic becoming brittle. It can be deposited on the surface of the friction material to form a film, which can effectively reduce abrasion. Zinc Sulfide is used as an additive in automotive brake pads to reduce noise and shock of brakes and improve tenure of use.

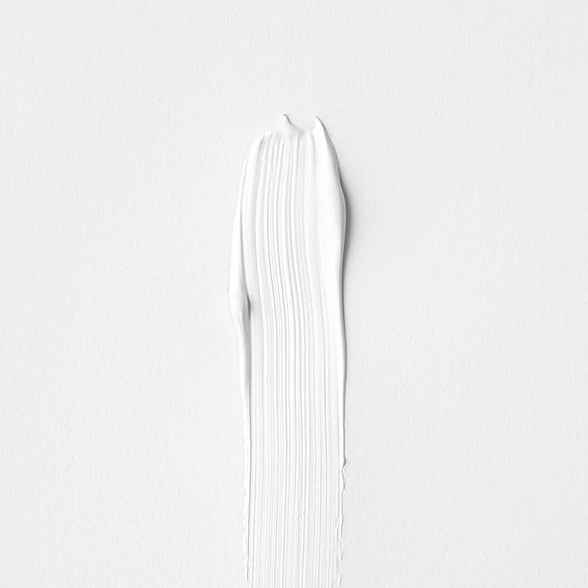

Paints and coatings

Excellent Optical Performance: LS-G25 is a unique white pigment that can be used together with optical brighteners to make brighter whiteness.

Prevent Cracking: LS-G25 has high thermal conductivity and keeps the coating at appropriate temperature to avoid cracks.

UV-Curing Performance: Traditional white pigments will prevent UV light from entering the coating’s inside layer. Therefore, traditional white or colorful coating can not use UV curing technique. But LS-G25 allows more ultraviolet light enter into the coating interior, and triggers cross linking reaction of the inside photoinitiator. It can also reduce dosage of other additives so as to reduce the cost.

Modified Plastic Fields

LS-G25 has high thermal conductivity when used in polyolefins which can help protect polymers against thermal degradation and it is suitable for plastics in LED. LS-G25 has lower Mohs hardness than TiO2. So it can be used in all glass-fiber-reinforced plastics (GRPs) which require good tensile strength and other mechanical properties. With lubricating properties, it can protect machines and moulds from abrasion. TiO2 will reduce the tensile strength of the material, because the hardness of TiO2 is higher than glass fiber. And it will destroy the structure of glass fiber when producing, which will affect the impact bending strength of the material. Glass fiber is harder than zinc sulfide. Zinc sulfide will not affect the glass fiber, and glass fiber reinforced can still maintain its mechanical properties.

3.Packaging and Storing

Compound Paper Bag : 25 kg/pack